III - Missions

My main task in this lab is to make measurements of the open sockets and measurement calibration in insertion and extraction with freelancing and pin, measuring the strength of a leg, compared with ANSYS and determination by calculating the coefficient of friction on the pin and the contact.

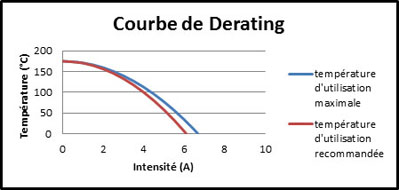

One of my side missions is to carry out heating tests on the connector to determine the heating coefficient k. It is important for the company to know this factor because it creates curves Derating then the company provides to its customers.

These curves are a notice allowing customers to know under what conditions they can use the connectors. For example, a connector having a class of 200 ° C, that is to say, to stay in good working condition, the temperature of the connector must not exceed 200 ° C. If for intensity of use, the connector is heated to 180 ° C and the customer places the connector in an environment of 40 ° C, the temperature of the connector will exceed 200 ° C. It will no longer be able to function properly and this can have serious repercussions. It is therefore necessary to provide comprehensive information to the customer on the use of products supplied by Souriau.

I also had to perform tensile measurements to breaking ground on rings, and we want to test two different types of ring mass, with and without flat because there are too many breaks when mounted to the connector assembly. Resistance measurements of an insert to failure, a test lock seaming, and also a measure of resistance.

(All testing procedures that I made are in the annexes).

- Bilan de la mission

In this course, I realized the usefulness of knowing the coefficient of friction of a bush over a rod, because it allows the calibration of master sockets and thus optimized.

This is an investigative measure which allows us to control and calibration measurements, if you want a stronger or weaker calibration, the factors that influence the measurement is well known. And we therefore have the ability to better control the external conditions that come into play in making sockets.

This method is still subject to many uncertainties that accumulate at each step of measurement, either calibration or thrust on lip.

But I was able to develop a test protocol that allows you to quickly control the friction coefficient of the workpiece and the desired batch. And also to identify the factors on which the coefficient plays, hence its usefulness.

Attached my warm-up measures have contributed to the complete catalog of the company on the connectors and different types of gauge, these values are often requested by the client for proper functioning, and as there are always new connectors, the company must be up to date in this list.